Aalto Fablab is the digital fabrication laboratory of the Aalto University. It is based on the classic MIT Fab Lab concept, has all the machines listed in the 100K fab lab specification, has open days and hosts Fab Academy thus being an active node in the global fab lab network.

See more, follow @aaltofablab on Instagram

Services

Of course you can visit us just like that during our opening times, but we are usually busy with something and the best way to make sure that you will have a meaningful conversation is by booking time with us. Take a look at the options below. If none of the options work for you, contact one of us directly via email.

Fablab Tour

If you are new to the world of fab labs, you can visit us and we will tell you what it is all about. Use the Book a tour option below to schedule a meeting.

Machine Introductions

If you know what a fab lab is and you want to use one of our machines, make sure that you acquire a permit. Even if you have used a machine before, we want you to know the specific way we make it work at the Aalto Fablab.

Machine Booking

You got the permit and it is time to get to work. Make sure that the machine you want to use is available by using the Book machines option below.

Project Consulting

If you are unsure how Fablab can help your project, you can book an individual project consulting session with one of us. We will hear you out and try to provide an adequate response to the problems you are facing.

Courses

We offer a Digital Fabrication minor that works as an academic overlay for the global Fab Academy course. The minor focuses on skills needed to use the Fablab to its full potential.

Tell me more!

It is not just the machines, but the knowledge around them. From idea to CAD and CAM design to fabrication with one or all the machines, electronics, programming and system integration – that is what you should try to get out of it.

For whom?

Lab is generally open the students of the Aalto University, but provides space and machine time to everyone else during open days. Membership options are also available (send us an email to find out more). Students, members and staff can book the machines (see Booking in the sidebar).

What can I do there?

It is a place where to make (almost) anything. You can learn and use each machine or fabrication method individually; combine your ideas with CAD/CAM skills and use different machine for every part of your project that requires it. Learn all the skills individually or via joining the Fab Academy – the choice is yours.

Things you can do at a fab lab include the following.

- Vinyl cutting stickers for your laptop, t-shirt or flexible circuit board.

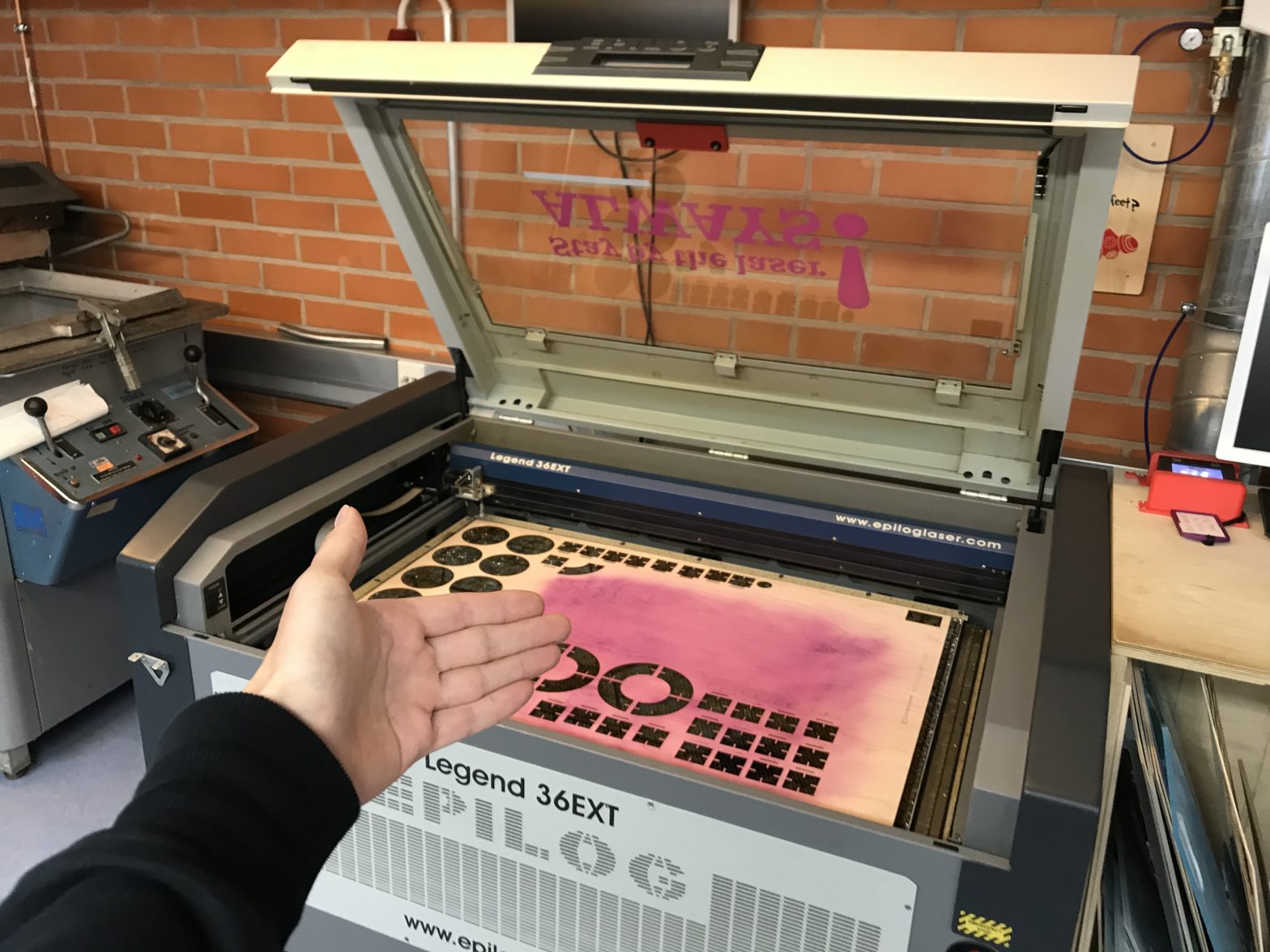

- Laser cutting complex parts for design, engineering or jewellery.

- 3D printing custom parts that are hard to make otherwise.

- CNC milling finger-joint furniture and 3D objects such as molds for vacuum forming or miniature landscapes for architecture.

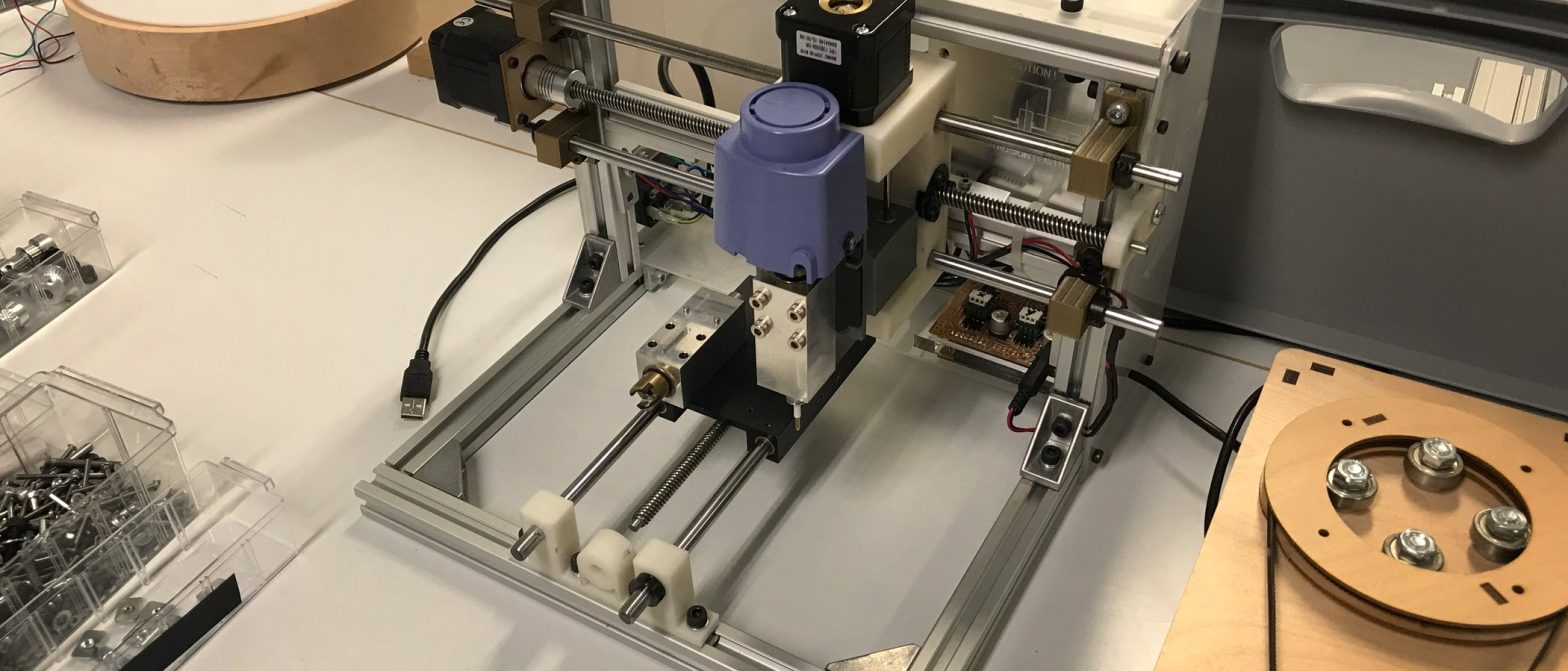

- Precision milling 3D objects and circuit boards.

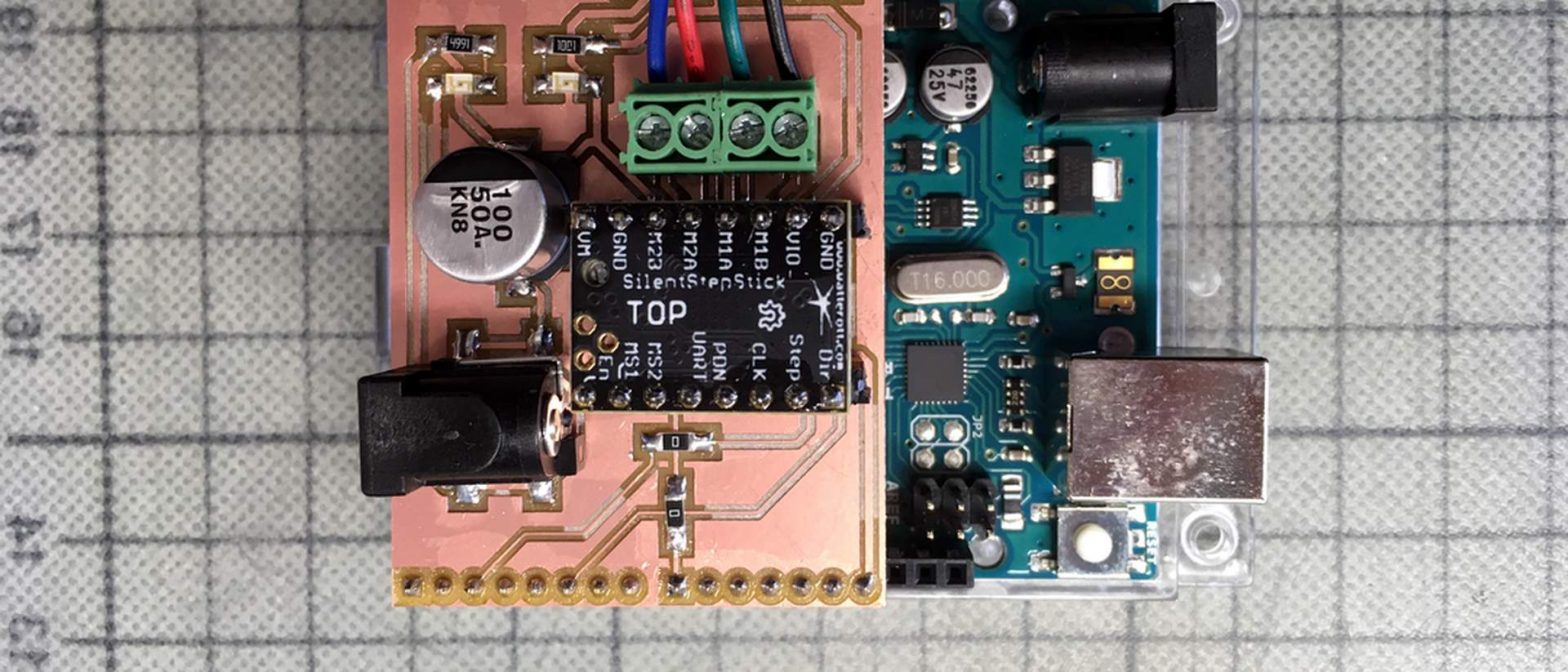

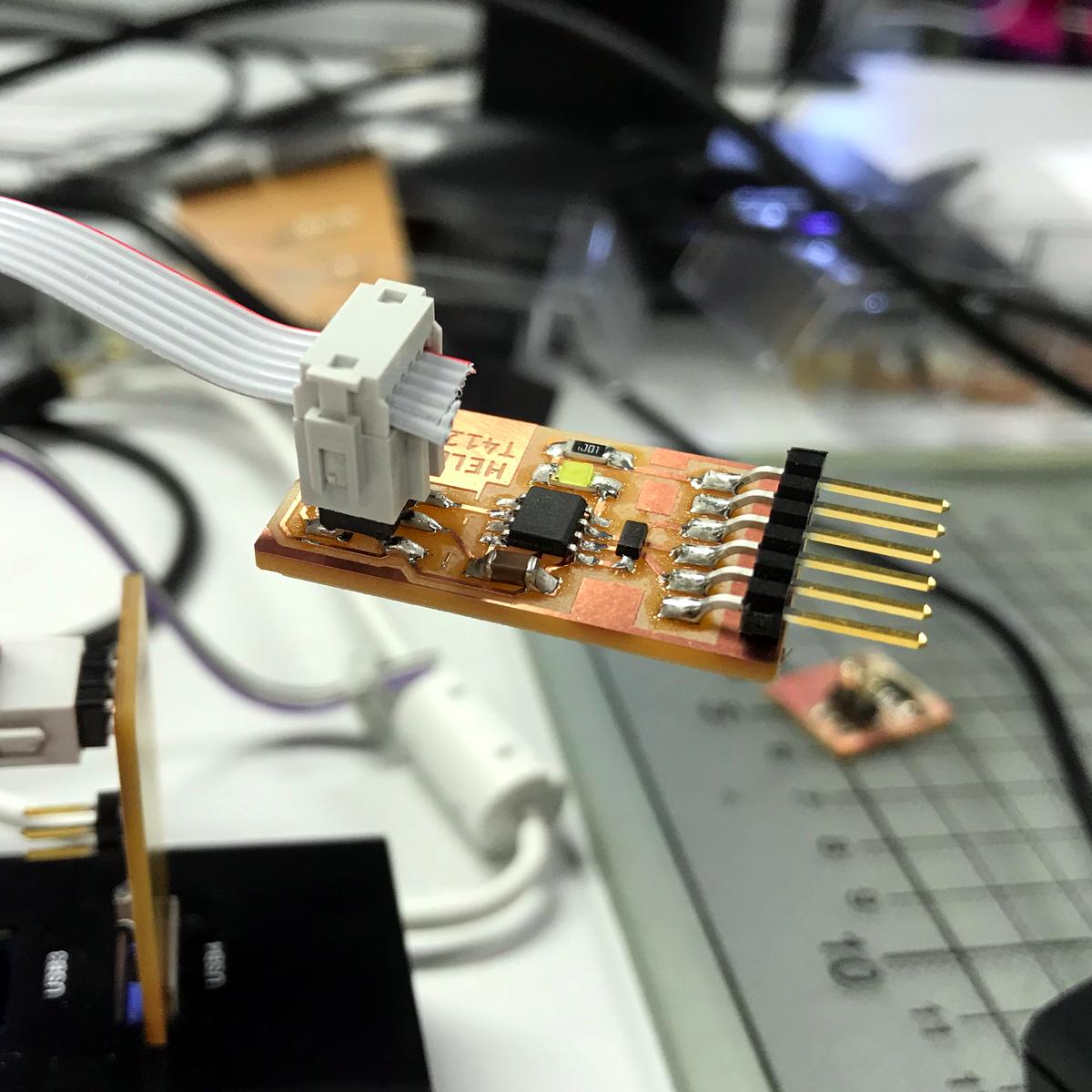

- Design and produce electronic circuit boards to drive motors, sense the environment or connect to your pocket calculator.

- And more!

Fablab Orientation

There are several ways how you can learn more about and get access to Aalto Fablab. 1. Introduction Sessions We offer…

Electronics Lab

Since Set Design Workshop and Aalto Fablab now live under one roof, the electronics lab is a shared one and can be found…

PCB Production

Bring your electronics experiments to the next level with the Aalto Fablab PCB production capabilities. We have two milling machines (Roland…

Fablab Courses

We offer a Digital Fabrication minor that started as an academic overlay for the global Fab Academy course. The minor focuses…

How do I get started?

Fab lab is a shared space and it can be used in combination with any course that requires digital fabrication. We offer introduction sessions for those who want to get started with a specific machine and Fab Academy to those who want to learn to use the fab lab to its fullest.

Please visit our Orientation product page to learn more!

Courses

Fab Academy is a fast paced, hands-on learning experience where students learn rapid-prototyping by planning and executing a new project each week, resulting in a personal portfolio of technical accomplishments (from Fab Academy web site).

We offer a set of courses that provide the academic overlay of the Fab Academy. Please visit our Fab Academy product page to learn more!

Equipment

Aalto Fablab has all the machines to qualify as a real fab lab. Click on the links below if you are interested in a specific machine or choose one of the products.

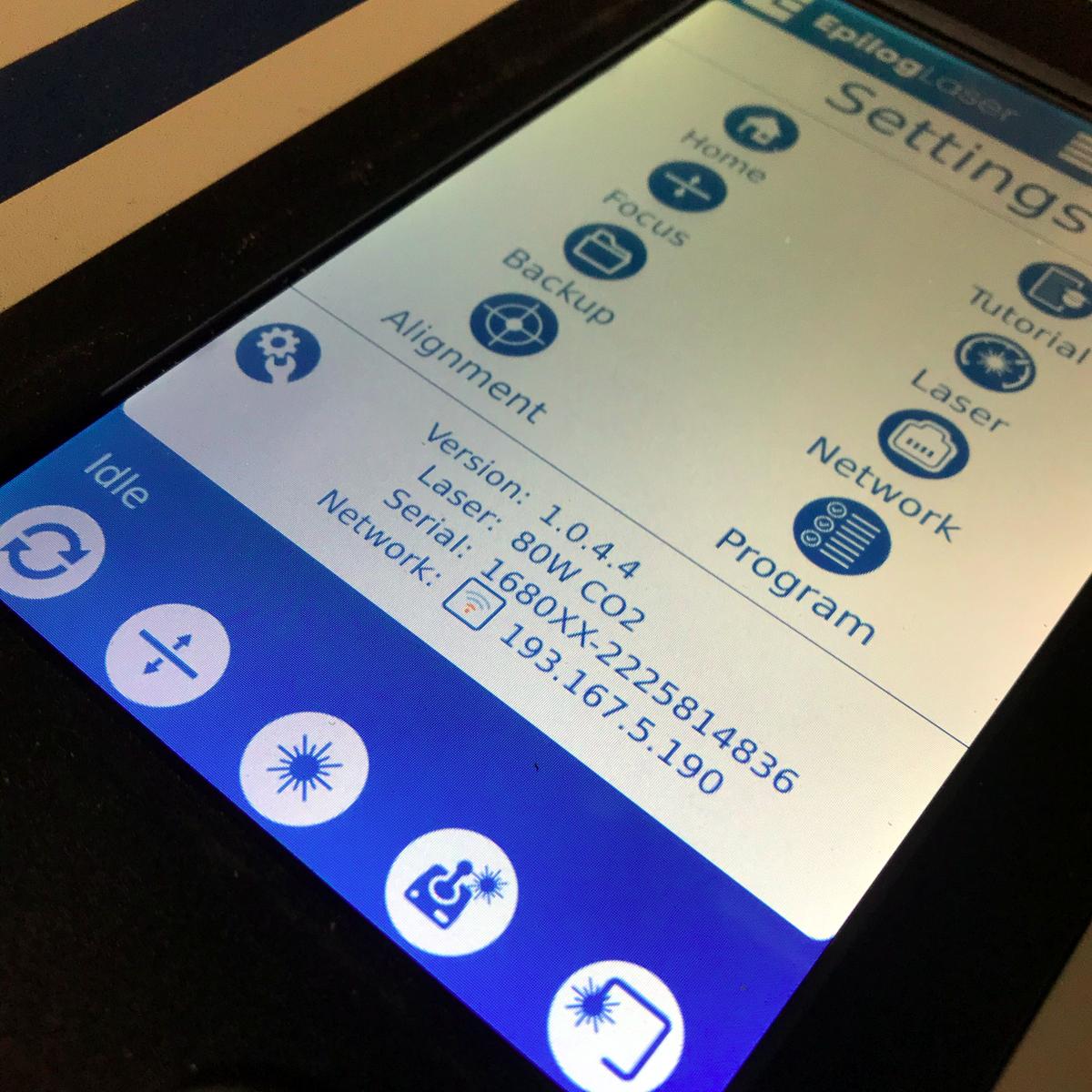

Computer-Controlled Cutting

- Roland GX-24 Vinyl cutter

- Roland BN2-20A Vinyl cutter and printer

- Epilog Fusion Pro 48 80w Laser cutter

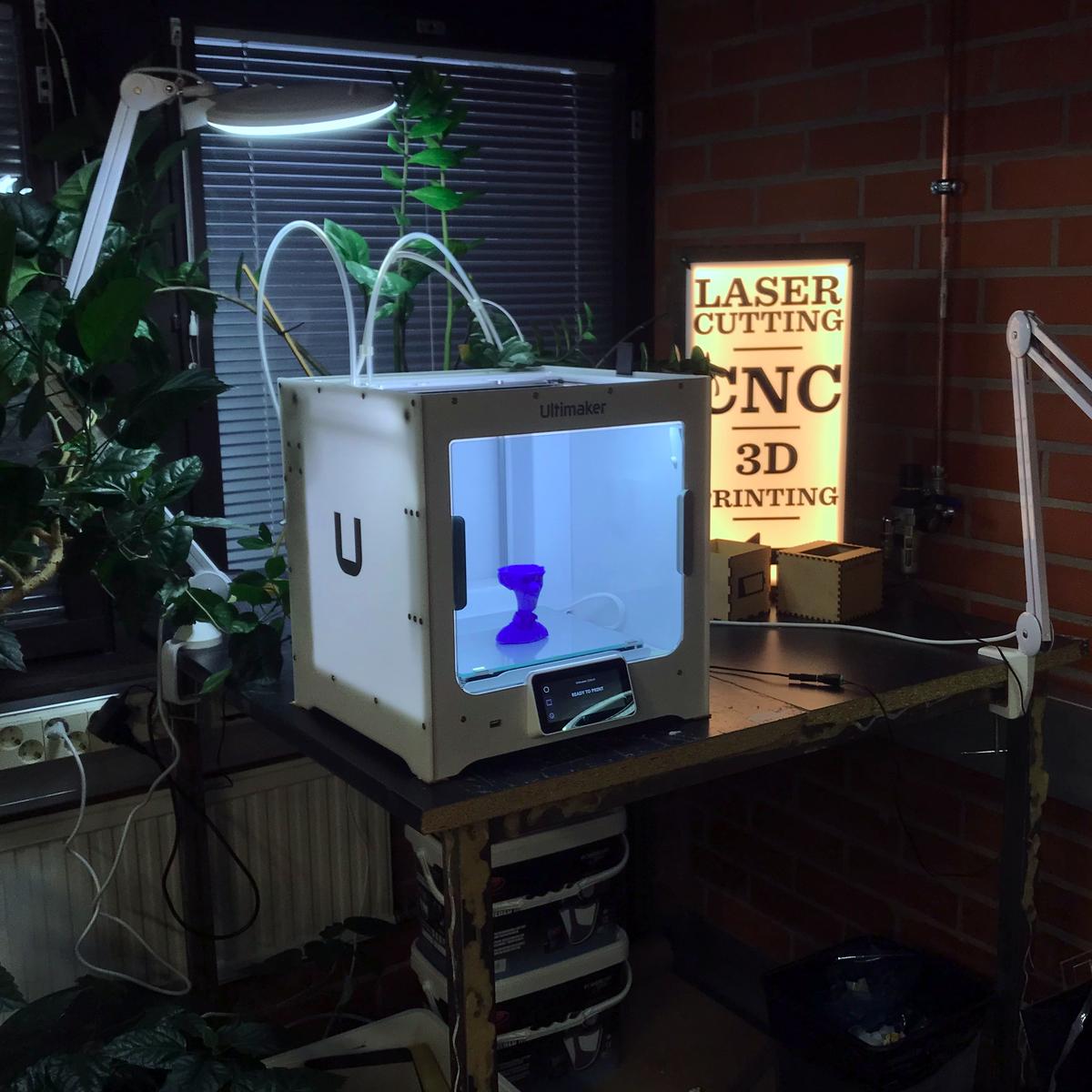

3D Printing (FDM)

- Prusa MK4 (3 units)

- Prusa Mini (3 units)

- Ultimaker 2+ Extended

- Ultimaker 2+ Connect (2 units)

- Ultimaker 3 Extended

3D Printing (SLA)

- Formlabs Form 2

- Formlabs Form 3

Computer-Controlled Machining (CNC)

- Recontech 1312 milling machine

- Bungard CCD/2 PCB milling machine

- Roland Modela MDX-40 precision milling machine

- Roland monoFab SRM-20 precision milling machine

Electronics Workbench

- Microscope

- Soldering stations

- Oscilloscope

- Power supply

- Electronic components

- Logic analyzer

Vacuum Forming

- CR Clarke 750FLB Vacuum former

- CR Clarke 145 Profile cutter

Materials

Here at Aalto Fablab using the machines time is free of charge, but you have to pay for the materials. Payment options include payment with card or an internal invoice. For an internal Aalto invoice we need a project number and cost center code.

Project number. The project is a basic element of the university’s internal accounting. All activities take place in projects and almost all accounting exports have a project number.

Cost center. Financial reporting according to different organizational units is based on the use of cost centers. The institution or school is reported on the basis of its cost centers. One Cost Center contains several projects.

Below you can find a list of materials that are usually there. Contact the workshop master to make sure there is enough stock for your project.